Understanding the Role of Medical Disinfectant Manufacturers

The advent of advanced medical technologies has equally paralleled a growing emphasis on maintaining a healthy environment. The role of medical disinfectant manufacturers has become crucial in ensuring that medical facilities remain safe, hygienic, and conducive to patient care. This comprehensive article delves into their significance, innovation, and impact on public health.

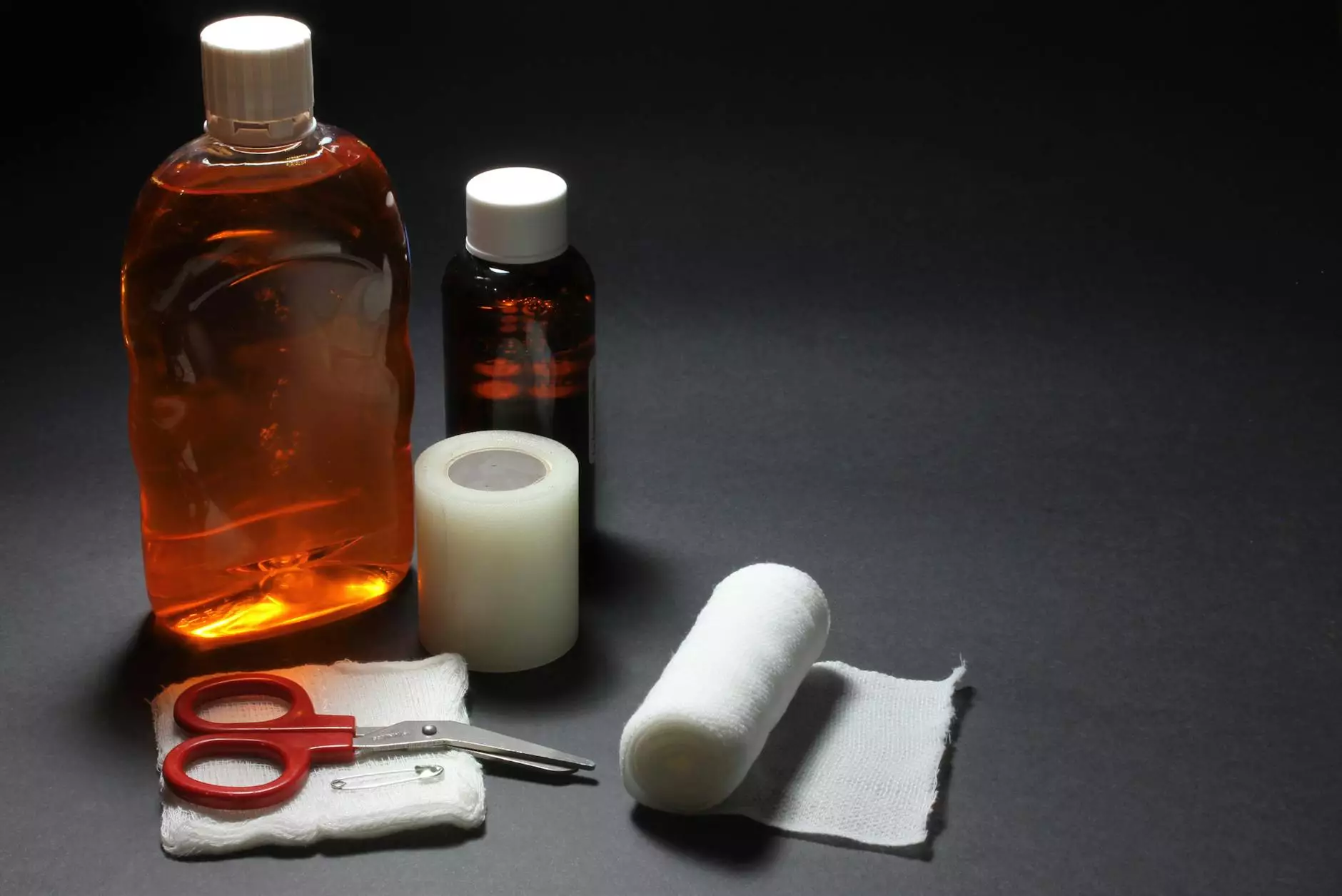

The Importance of Disinfection in Healthcare

Disinfection is a critical component in healthcare settings. It helps to reduce the risk of infections, which is vital for patient safety and the overall effectiveness of medical treatment. Various types of microorganisms, including bacteria and viruses, can thrive in medical environments; thus, effective disinfectants are required to manage these risks.

Types of Medical Disinfectants

- Alcohol-based Disinfectants: Commonly used for hand sanitization, these disinfectants are effective against a broad spectrum of microbes.

- Chlorine Compounds: Utilized primarily for surface disinfecting, these are famous for their strong antimicrobial properties.

- Quaternary Ammonium Compounds: These are often used for cleaning and disinfecting surfaces in healthcare settings.

- Hydrogen Peroxide: This disinfectant has gained popularity for its ability to eliminate pathogens without leaving harmful residues.

Key Responsibilities of Medical Disinfectant Manufacturers

Manufacturers in the medical disinfectant sector have a diverse range of responsibilities that extend beyond merely producing disinfectants. These include:

1. Compliance with Regulatory Standards

Medical disinfectant manufacturers must adhere to stringent regulations established by health authorities. In many countries, this means complying with guidelines from organizations such as the FDA, EPA, or corresponding regulatory bodies. These regulations ensure the safety and efficacy of the products, fostering trust within the healthcare community.

2. Conducting Research and Development

R&D is at the heart of innovation in the medical disinfectant industry. Continuous investment in research allows manufacturers to:

- Develop more effective formulations.

- Increase the speed of action against pathogens.

- Ensure that products are safe for both users and patients.

3. Creating User-Friendly Products

Healthcare professionals often operate under extreme pressure. Hence, medical disinfectant manufacturers focus on developing products that are easy to use. Features that enhance user experience can include:

- Quick-drying formulas

- Scent-free options to minimize irritation

- Packaging designed for ease of application

The Role of Quality Control

Quality control (QC) is essential in maintaining the integrity and effectiveness of medical disinfectants. Effective QC processes ensure that every batch of product meets predefined standards. These standards are typically based on:

- Effectiveness: Disinfectants must display proven antimicrobial efficacy against a broad range of pathogens.

- Safety: Products must be non-toxic and safe for healthcare workers and patients.

- Stability: Disinfectants should maintain efficacy over time when stored according to manufacturer guidelines.

Challenges Faced by Medical Disinfectant Manufacturers

The field of medical disinfectant manufacturing presents unique challenges:

1. Continuous Evolution of Pathogens

Pathogens are constantly evolving, which necessitates the development of new disinfectant products that can effectively combat resistant strains. Manufacturers must be agile in adapting their formulations to address these emerging threats.

2. Environmental Concerns

Growing environmental awareness has led to increased scrutiny of the chemical ingredients used in disinfectants. Manufacturers are responding by developing greener solutions, such as:

- Biodegradable ingredients

- Eco-friendly packaging

- Concentrated formulas to minimize waste

The Future of Medical Disinfectant Manufacturing

As the healthcare landscape evolves, so too will the role of medical disinfectant manufacturers. The future is likely to focus on:

1. Smart Disinfection Technologies

Innovations in technology are paving the way for smart disinfection solutions. These may include:

- Automated disinfection robots

- Real-time monitoring systems to track disinfection efficacy

- Integration with health care IT systems for better data analysis

2. Personalized Disinfection Protocols

Future products may allow for a more personalized approach to disinfection, ensuring that different areas of a healthcare facility receive tailored solutions based on their unique risks and requirements.

The Impact of Medical Disinfectants on Public Health

The use of effective disinfectants in healthcare settings plays a critical role in controlling healthcare-associated infections (HAIs). The ramifications of improved disinfection practices extend beyond individual health; they contribute significantly to:

- Lower hospitalization rates, thus reducing the burden on healthcare systems.

- Enhanced overall safety, fostering public confidence in healthcare providers.

- Reduction in healthcare costs, as effective disinfection leads to fewer infection-related complications and treatments.

Conclusion

In conclusion, the contribution of medical disinfectant manufacturers to the healthcare sector is indispensable. From their rigorous R&D efforts to their commitment to quality and safety, these manufacturers significantly influence the efficacy of infection control strategies. As the industry progresses, manufacturers must remain adaptable and innovative to meet the evolving needs of healthcare providers and patients alike. The health of communities relies heavily on the effectiveness of these disinfectants, underscoring the need for continuous improvement and commitment to excellence in this critical sector.

For more information about top-quality medical disinfectants, consider exploring medalkan.com to discover innovative products designed to elevate sanitation standards in healthcare.